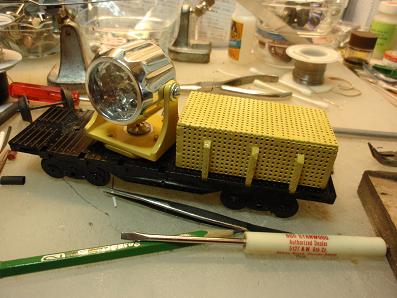

These pictures and descriptions show a kit bashing project combining a plastic Marx flatcar

with an LED flashlight to make a spotlight car for my MOW train. I really thought that this

project would be simple and quick. I had no such luck.

The basic components are a flatcar body

and a small, LED flashlight. It seemed to me that once I had these two pieces, the rest of the project would be very

simple and very fast.

|

This center-rail pickup is supplied by Robert

Grossman.

|

Oh Gosh, now I need to pick up power from the

outside rails.

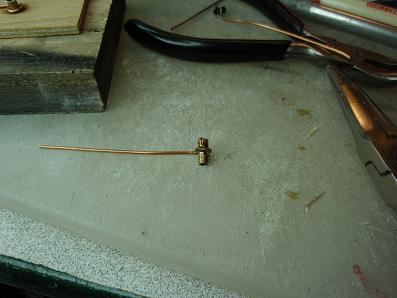

This gadget is a soldering jig used to hold a piece of brass tubing while I solder a solid copper wire to it.

|

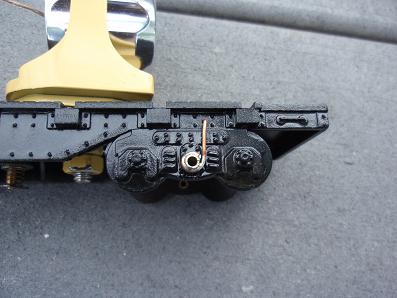

Here is 1 completed wheel pickup assembly.

|

And here are all four of them. The project has

already taken more time than I had expected. The plastic car body is a good insulator.

|

The original axle holes were worn and

elongated. By installing the pickup assemblies,

I repaired that damage as well as making contact with the outer rails. The only lubrication for these is graphite

powder. Oil would insulate.

Drilled a hole for the tubing and a hole for the wire. Secured with ACC super glue.

|

Here are the solid wires that collect

the connections to the outside rails into a single point.

|

I used angle aluminum to make the

yoke that holds the business end of the flashlight. Lots of sawing, filing, drilling and tapping.

|

This photo shows the light bezel mounted and

the connections to center rail and outside rails routed up to power the light.

|

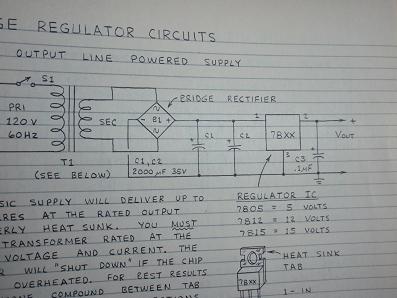

Its another hitch. For normal LED power

we just need a resistor to limit the current. But, this flashlight uses 3 AAA cells for power and no outside resistors.

I don't have a reliable way to measure current, so, I decided I needed to build a regulated power supply that would

accept track power and provide something very close to what the 3 AAA's would do. Time to hit the books.

|

A simple circuit to produce a regulated

power supply. I used a 7805 to give me 5 volts and then put a couple of silicon diodes in series to drop the voltage

to about 4.6. That is what the batteries produced, together.

|

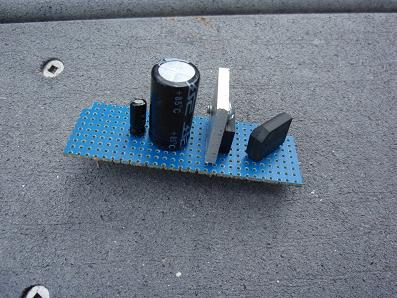

This is the second try. The VR I got from Radio Shack

was a bad part and fried the first LED flashlight. Its a good thing I had two of them. I bought better regulators from

Jameco and they work just fine.

|

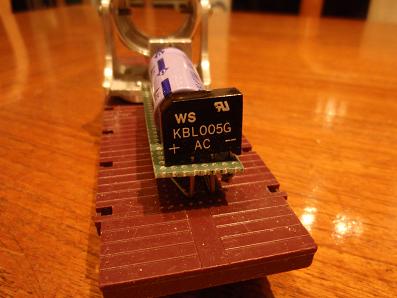

Here is the diode bridge on the input side of the first try.

|

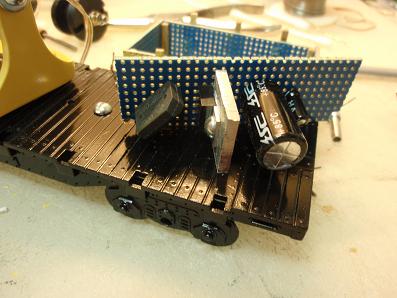

This is the second try with the better parts. The

aluminum chunk is a heat sink for the regulator. The capacitors keep the power smooth.

|

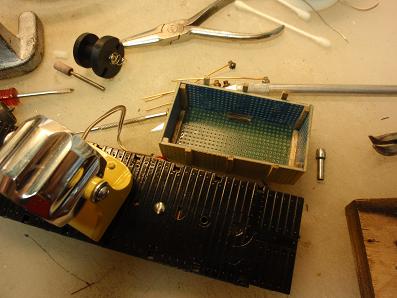

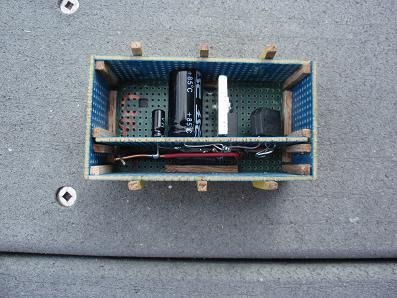

The circuit will produce heat, so, I need a cover that

permits some ventilation. I used perfboard and reinforced the corners with some wood strips.

|

More wood strips keep the circuit board aligned.

|

These are the connections to the backside of the

LED portion of the flashlight.

|

Here is the front view at the same stage in the process.

|

The circuit cover fits into the stake holes on the side of the flatcar.

|

Another view ready for wheels and a test.

|

Here is the spotlight looking up at its big brother.

|

Assembled, decorated, tested and fully functional.

I expected the project to take a couple of evenings. In real time, it was more like 4 months. I can't say I recommend

it, but, it is done and it was fun. The voltage regulator protects the LEDs from excess voltage, provides a constant intensity

and flicker-free operation.

|