|

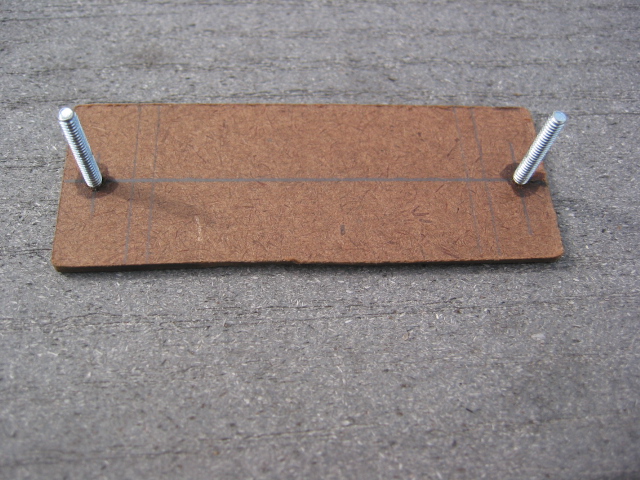

The cleaner works by sliding a Masonite pad along the rails as the car is towed over the tracks.

The pad is allowed to "float" over the rails. That is, the pins (bolts in this case, but, more

often brads or finishing nails) fit loosely into holes in the underframe of the car. Where the track

has bumps, curves, turnouts, vertical transitions and (shudder) imperfections, the pad can follow

the surface.

|

|

This pad is mounted by way of flat head machine bolts. They were handy at the time. The heads

are countersunk to be flush with the bottom of the pad and secured with a drop of adhesive.

The pad is slightly wider than the track gauge to assure some overhang and to avoid binding

around curves and through turnouts. The edges are very slightly beveled for the same reason.

|

|

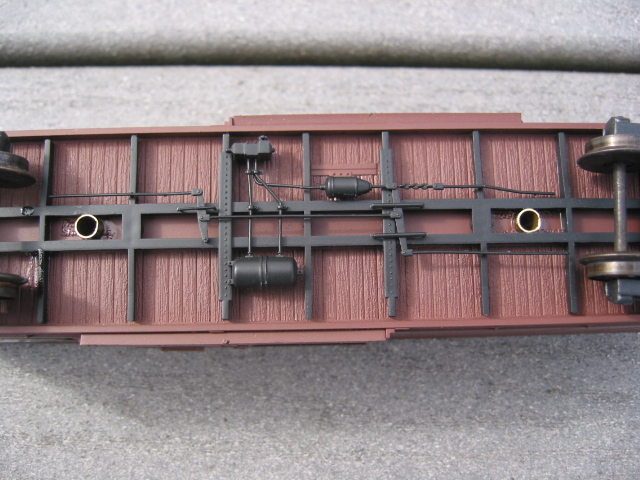

As the car moves over the track, the pad moves up and down. That action can cut through a plastic

chassis. For most cars, I prefer to use a metal chassis. In this case, the car had a plastic floor,

so, the holes were lined with brass tubing. The brass is secured to the floor with adhesive.

|

|

|

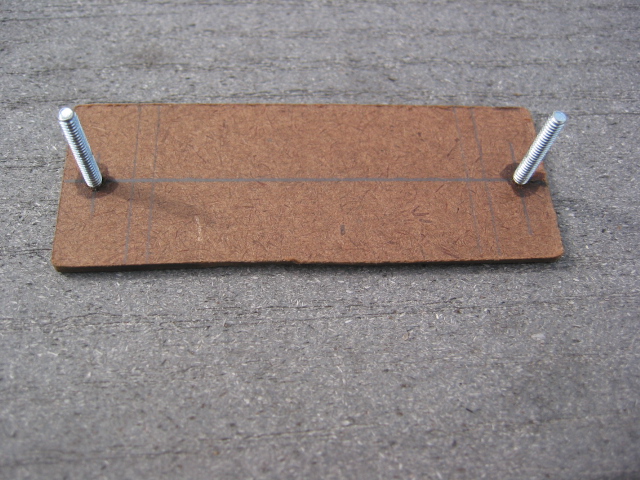

You can see the accumulation of gunk on the textured side of the pad. From time to time,

clean it out using a dry toothbrush.

|

|

|

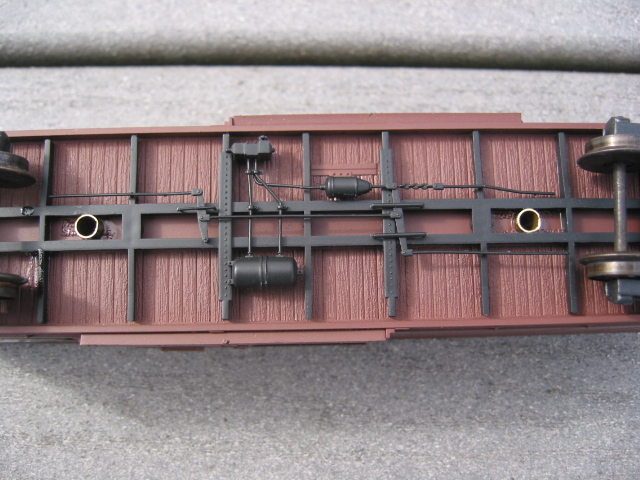

This installation is in a Marx, O-Gauge plastic box car with a sheet metal floor. The mounting nails

are offset from the center line to avoid the center rail. Since the floor is tinplate steel, there is

no need for inserts. Just drill the holes slightly larger than the diameter of the nails.

|